I’m often asked how prescription lenses are cut into the various shapes of frame available. At Lawrence and Harris, we are lucky enough to have our own glazing lab within our Caerphilly Practice. The vast majority of frames including rimless, semi-rimless and sports glasses are glazed by Terry our glazing lab technician. Usually only safety glasses are glazed elsewhere.

Once you have chosen your frame and lens combination, your lenses are either ordered from the lens supplier or picked from our stock. The lenses are delivered to the practice in uncut form (a circular lens much larger than the final shape needed). When they arrive in the practice they are checked against your records to ensure they are correct before they pass onto Terry to be glazed into your frame.

The lens shape is firstly measured mechanically or optically so that the computer controlled lens grinding machine has a an accurate image of the lens before cutting begins. The lens is placed within the machine where the prescription is again checked for accuracy. Measurements, such as the distance between your eyes and height of your pupil relative to the frame are entered in to ensure the lens sits exactly in the correct position in front of your eyes.

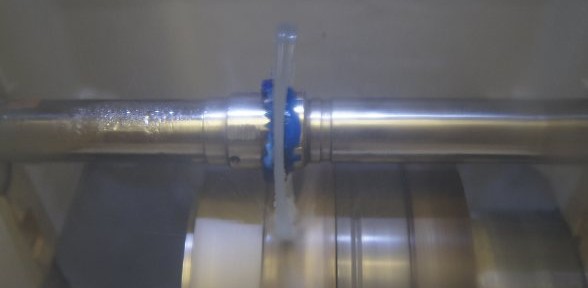

The lens is then placed into the grinding machine which uses the shape measured earlier to cut off the unwanted material and edge a groove around the edge of the lens so that it fits snugly in the frame.

If a rimless frame is chosen, the lens goes on to be drilled so that the frame can be secured to each lens by screws or suction plugs.

Finally the prescription and quality of lens fit are checked before being cleaned and prepared for you to collect. The whole process can take from 15 minutes up to 60 minutes depending on the complexity of the job.